As a plastic industry enterprise, VMT has often encountered the view that the industry is not traditionally thought of as responsible or environmentally friendly. Because plastic is in any case needed in the world, VMT wants to be involved in increasing the responsibility of plastic use.

“We want to be a pioneer in the field and build a profile as a top specialist in recovered secondary raw materials. This is what all of our development efforts and responsibility measures also attempt to achieve”, VMT CEO Marja Haapanen says.

Plastic products manufactured by VMT are used for machine and device components in industrial production processes. Using plastic for such applications makes sense, because the materials need to be easy to form into shape and light in weight.

“Our product development is always carried out from the perspective of sustainable development. We optimise the use of plastic in a way that ensures that we are always using the correct material that suits the application. So, our product development is geared towards making products as optimal and functional as possible and achieving the required strength characteristics while using as little plastic as possible. We also make sure that the products last for as long as they are needed, maximising their service life”, Haapanen explains.

A recycled raw material is an environmentally friendly choice

The responsible approach adopted by VMT is highlighted in particular by the dramatic increase in the use of secondary and recycled raw materials. A few years ago, only about 20 percent of the plastic raw material used by VMT consisted of recycled materials, while the remaining 80 percent consisted of new raw materials. Now, the numbers have been inverted – 80 percent of the plastic products manufactured by VMT are made using recycled plastics.

Thanks to improvements in plastic recycling, the range and availability of raw materials are expanding and improving. Adopting new materials for use does however require plenty of development work by VMT, but success in such efforts has increased the use of secondary raw materials dramatically.

“Our goal is to increase the volumes of products made with secondary raw materials even more”, Haapanen says, stating that there will however always be some technical products for which new raw materials cannot be replaced with recycled materials due to their characteristics.

“We are however continuously trying to increase the volume of recycled raw materials, and we work hard to accomplish this.”

The use of recycled raw materials is also supported by the knowledge that the sourcing of new raw materials will become more difficult and expensive in the future. At the same time, recycling is becoming more efficient, and machines make it possible to better utilise secondary materials.

“Recycled plastic already exists, so it is worthwhile to use it. As long as the raw materials are kept pure during the recycling, they can be used again and again, countless of times.”

Investing in product development is worth it

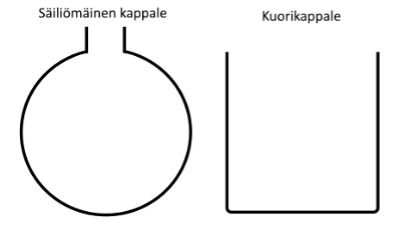

VMT uses two different processes, injection and blow moulding. Recycled raw materials have been traditionally available for injection moulding, and it is also easier in principle to use recycled materials for injection moulded products. As for blow moulding processes, it has been somewhat difficult to obtain secondary raw materials.

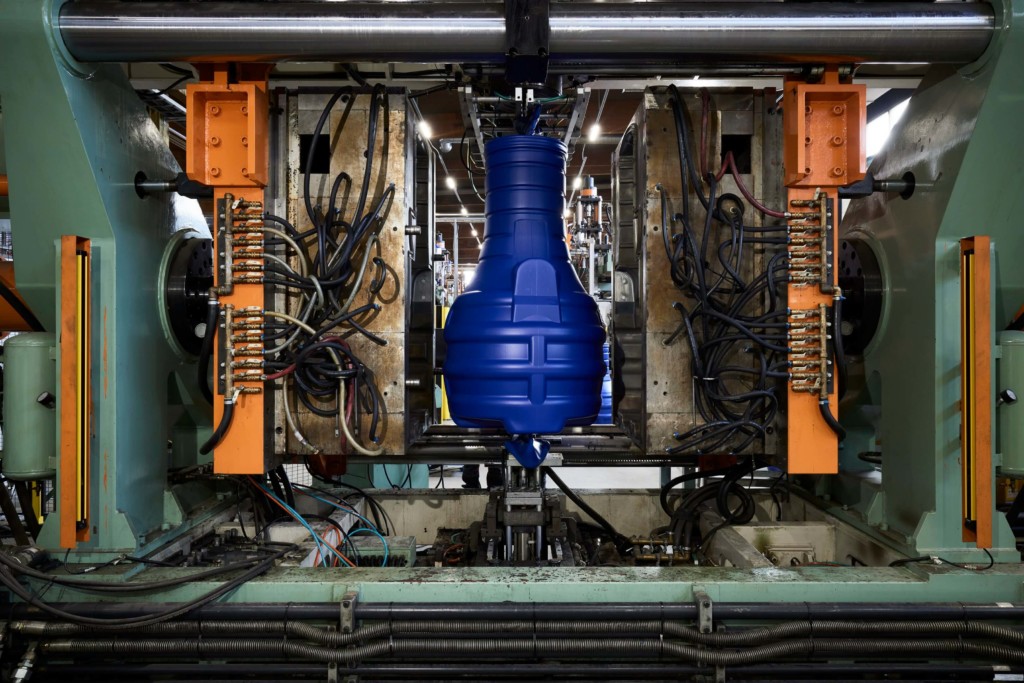

“The blow moulding process is also more difficult to control, and in the past, we have been able to only use certain fractions to make products. We have been working hard here at VMT to gain control of the blow moulding process with recycled materials as well, and as soon as the suitable raw material is found, the hard work will begin to pay off”, Haapanen rejoices.

The Finnish secondary raw material Fortum Circo that can be used for blow moulding utilises waste plastic collected from consumers. Circo mainly contains crushed plastic package waste, such as detergent bottles and other similar containers.

“We have been able to get Circo to work as the raw material for our blow moulding process, and we are using a lot of it now. The good thing about Circo is that its availability is guaranteed. Recycled materials often have the problem that you might get only one batch of the raw material. When we start the manufacturing process for a certain product, we need to be sure that the raw material continues to be available in the future as well, because our products are usually made for periods that last several years”, Haapanen explains.

Investments to tackle the carbon footprint

VMT’s internal recycling efforts have been at a good level for a while now. The company reuses almost one hundred percent of the waste material it generates. The waste material is taken straight to a crusher on conveyors and from there back into production.

“We have not been able to crush the largest products as part of our own production, so we have taken them to our partner in Kuortane for crushing and then back again to be used in production. We will be investing in a system this year that will be able to crush even such larger products”, Haapanen says.

“This will further improve the recycling and eliminate the need for additional transports, thus reducing our carbon footprint as well.”

Active efforts to ensure responsibility

VMT is continuously looking for ways to do things better in terms of responsibility and the environment.

“We always want to find small things that we can do to improve energy efficiency and the environment in general”, Haapanen confirms. The responsibility measures impact human resources affairs as well.

“We take care of our house in a way that helps everyone. We have invested in occupational safety, developing our payroll system, and improved the healthcare of our staff.”

However, there is still work to be done. Moving forward, VMT will invest in responsibility reporting in a way that makes it clearer to staff, partners, and customers what measures have been implemented.

“In the course of this year we will also look into measuring our carbon footprint and developing environmental affairs in a more systematic way, for example by using various certifications. We will talk about this in more detail in the spring”, Haapanen reports.