Injection moulding

Precise plastic products for technical applications.

Injection moulding – precise plastic products for technical applications

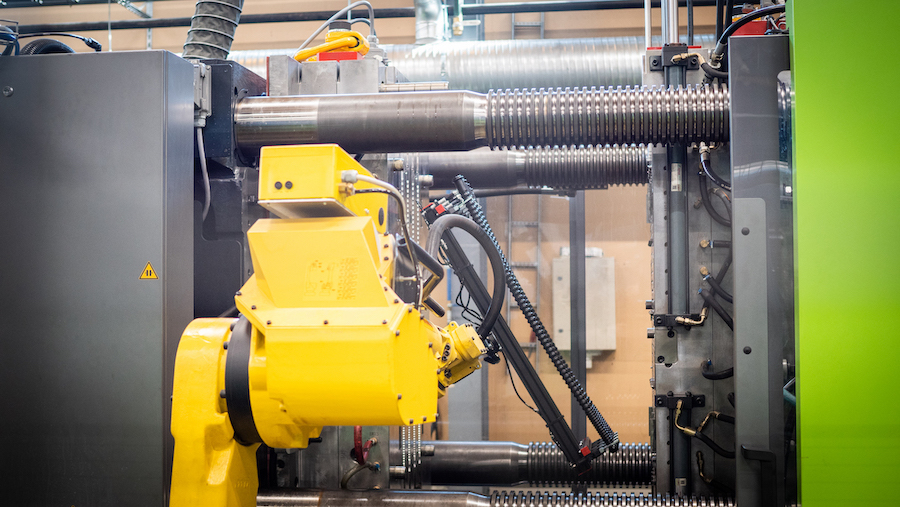

VMT Plastic provides various plastic solutions using the injection moulding method. The cost-efficient production process is founded on VMT Plastic’s automated injection moulding production, which is supplemented by our uncomplicated assembly and storage services. Get to know our injection moulding service – we are happy to help!

Agile expertise in injection moulding

Injection moulding, or injection compression moulding, is the most common manufacturing method of plastic products, which involves injecting the chosen plastic raw material into a mould. The process makes it possible to produce various plastic products for different industries quickly and precisely. The shape of the injection moulded product can be chosen freely within the limits set by the used moulding technique. Injection moulding is best for product series of more than one thousand pieces.

The possibilities and limitations of the injection moulding method and the used plastic raw material are always considered in the design of a new plastic product. The high quality of plastic products is ensured by using professionally manufactured injection moulds. Our competence and machinery make it possible for us to quickly carry out all required mould alterations and maintenance and repair works at our in-house moulding workshop. If you need it, we can also take care of product assembly stages and the required sourcing for sub-assemblies.

Always professional injection moulding

VMT Plastic’s strong competence in the design and product development of injection moulded products ensures that your plastic products are always completed cost-efficiently employing Finnish labour.

We provide

- good knowledge of raw materials – we use almost all technical plastic materials

- bespoke plastic product solutions

- product design and modelling services

- automated and cost-efficient injection moulding production services

- component sourcing and sub-assembly, i.e. ready-made plastic product packages

- the widest possible selection of recycled materials for your product

- an efficient, high-quality, and environmentally friendly approach to the production of plastics.

Injection moulding for larger product batches

We understand that your plastic product is important for your business, regardless of whether the production batch or the product itself is large or small. The injection moulding method is good for product batches consisting of a few thousand to some dozens of thousands of pieces. Our machinery includes everything from small 20-ton injection moulding machines to large 700-ton machines – and of course everything in between.

The smallest plastic components we make weigh only a few grams, and the largest can weigh up to about 2.5 kilogrammes. We utilise a wide selection of technical plastic raw materials, the most common of which are polyethylene (HDPE), polypropylene (PP), polyamide (PA) or nylon, ABS, PBT, and POM, and most of which are also available with e.g. glass reinforcement.

The sizes of the products we make vary from a few centimetres to half a metre. The largest products made using injection moulding are about 50 by 50 centimetres, but we can also make narrower injection moulded components measuring up to a metre in length.

Investing in responsibility and automation

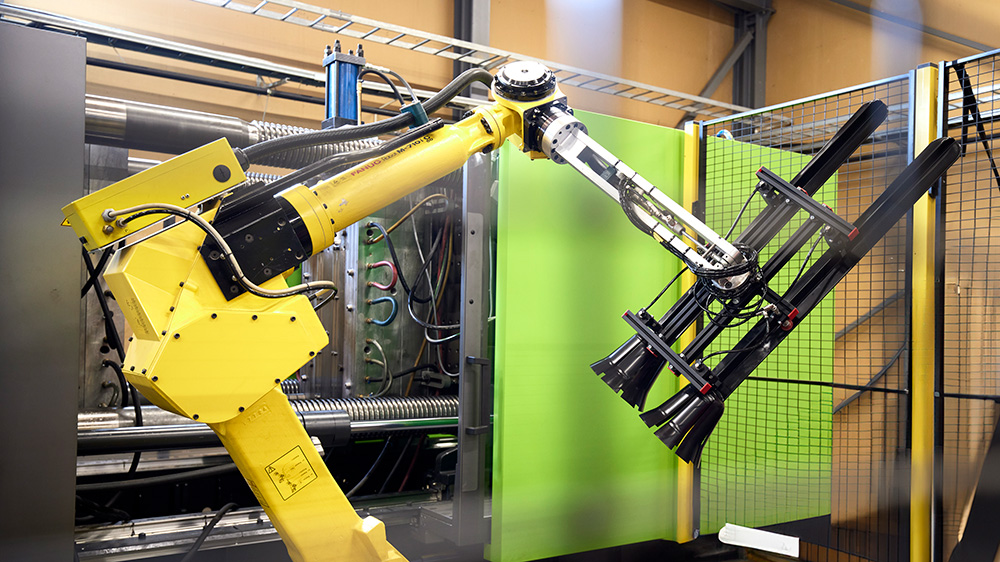

VTM Plastic has invested in new top of the line equipment, utilising automation and reducing wastage and losses to a minimum.

Developing our production is an on-going process, and the investments we make will

- improve energy economy

- improve cost-efficiency

- generate cost savings by means of robot-assisted manufacturing

- make it possible to create new product applications based on the manufacture of even larger products

- provide technical plastic solutions for special use conditions.

Our customer satisfaction relies on experienced professionals and an automated production process, which guarantee a high quality of products and a good level of supply security.

Dependable competence with raw materials

VMT Plastic knows plastic raw materials like the backs of their own hands. As such, we are always happy to help with the selection of plastic raw materials. We will tell you about the differences between different raw materials and how they impact for instance the price and speed of the manufacturing process. We also make it possible to use responsible recycled materials in your plastic products.

The most common plastic raw materials used by VMT plastic

Polyethylene and polypropylene are the most typical raw materials, but, as an agile operator, we can work with rarer ingredients as well. Don’t hesitate to ask more about the various raw materials and their possibilities.

- HDPE or polyethylene

- PP or polypropylene

- PA or polyamide

- ABS

- PBT

- POM

- TPE

- TPU

- PS

Plastic is a versatile raw material. In addition to various plastic compounds, raw materials containing fibreglass can also be used in products if needed. Using injection moulding, the right design, and e.g. fibreglass-reinforced polyamide, extremely hard and rigid products can be made. VMT Plastic is a leader in the use of recycled raw materials – if possible, we will use recycled raw materials in our injection moulding process as well.

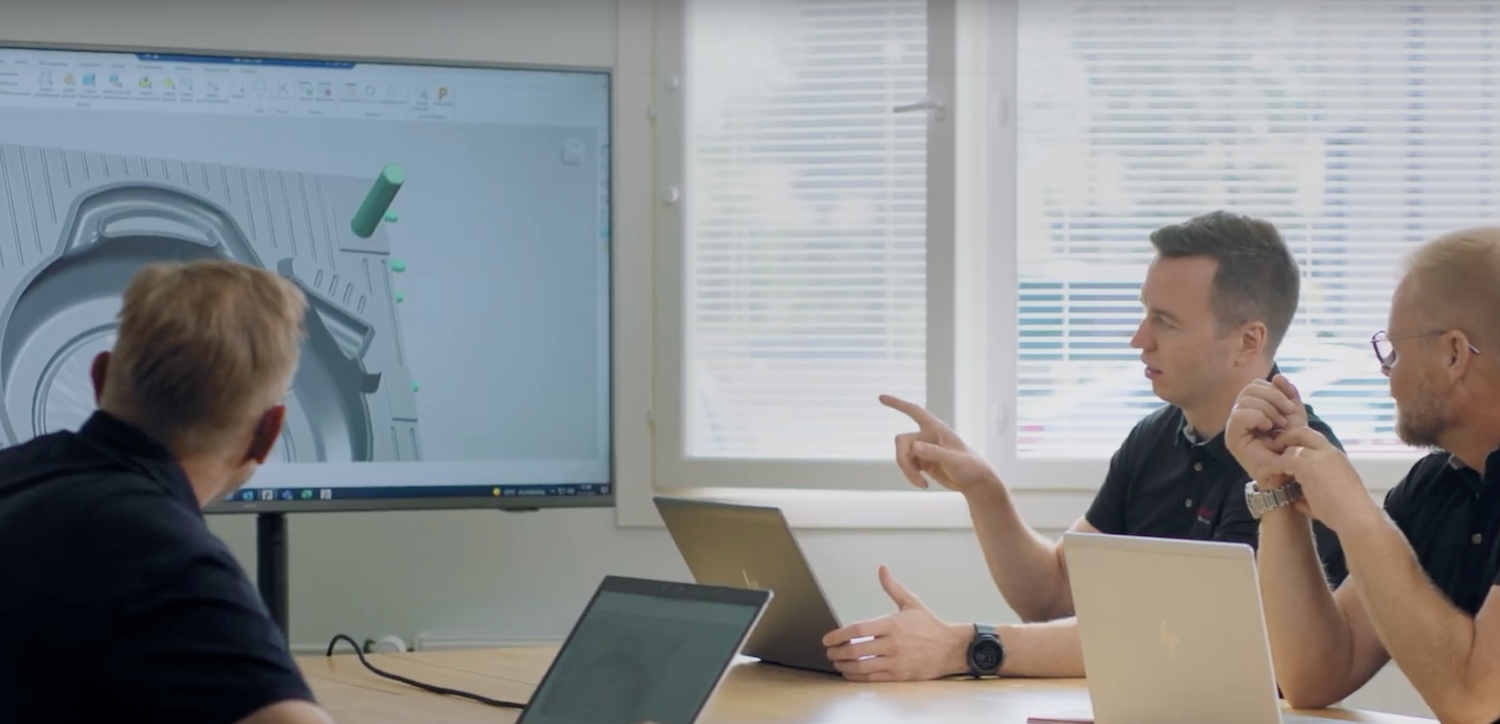

Developing products to best serve your business

Our strengths are in design and in our ability to see existing products through new eyes. We are always looking for new opportunities and perspectives in the design of pieces to cut costs and facilitate the manufacturing process. Even minor design changes can reduce the amount of raw material required, which will reduce the carbon footprint of your final product.

Working together on product design takes some of our customers’ time, but it is worth it. When beginning our product development partnership, we will review the boundary conditions for size and shape and specify the use purpose and conditions of the product. At best, you will receive in return a product that is lighter, better designed, and cheaper than before.

Don't hesitate to contact us.