Plastic product development – working together towards the best possible product

Product development services

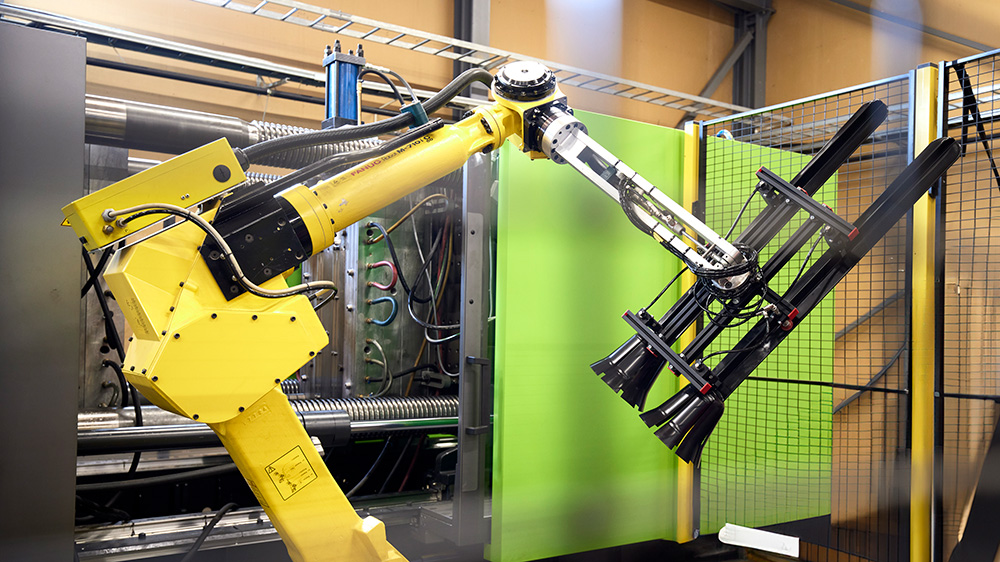

VMT Plastic’s product development services offer you a solution when you need help designing a new product or developing an existing product. Whether you start with a simple idea or a near-ready concept, our experienced product development team can provide you with clear answers and concrete solutions. We can help you optimise the manufacturability of your product, choose the right materials and production methods and save costs.

Product development supports successful production

Our product development process starts with your business needs. Whether it’s a new product idea or an improvement to an existing product, our product development team carefully assesses manufacturability, material choices and production methods. We draw on our long experience, extensive technical knowledge and moulding expertise to ensure that the final product meets – and often exceeds – your expectations.

Our product development is not limited to our own production methods of injection moulding and blow moulding. If we find that another manufacturing method is more suitable for your product, we will openly recommend it. This approach ensures that you always get the best possible solution without compromising on quality or performance.

Benefits of product development

VMT Plastic’s experienced product development team offers a bundle of benefits that will benefit your business in a variety of ways.

- Cost savings. A well-designed product can be manufactured more efficiently and with lower raw material costs. This is directly reflected in the price of the product and improves your competitiveness.

- Speed. With our experienced team, the product development process is fast and flexible. We can provide solutions and suggestions quickly to get your product ready without delays.

- Responsibility. We pay attention to the use of recycled materials and material efficiency. With the right solutions, we can reduce raw material waste and improve the ecology of the product without compromising on quality.

- Expertise. Our wide experience in different manufacturing techniques and methods enables us to find effective solutions quickly. This brings efficiency and innovative perspectives.

The earlier you involve us in the design process, the better and more effective solutions we can provide. Successful product development not only solves production challenges, but also creates new opportunities for your business.

VMT Plastic – product development versatility and experience

With over 50 years of experience, we are a reliable partner in product development. Our team’s expertise covers a wide range of plastic product design, mechanical design and moulding expertise. In addition, our flexibility and close cooperation ensure that we can meet your needs quickly and efficiently.

As a small but capable and agile player, we offer the expertise of a large organisation and the speed of a small organisation. This makes us a unique partner who truly understands your needs.

The key to successful product development is effective and open collaboration – VMT Plastic’s product development combines your business needs and the multidisciplinary expertise of our team into a functional plastic product.

Take the next step in product development

Let us help you turn your idea into a finished product. Contact our experts and let’s talk more!

Check also our assembly service!

Don't hesitate to contact us.