Recycled plastic helps reduce the carbon footprint.

Recycled plastic is a versatile and responsible raw material that can be used in many products. VMT Plastic knows recycled plastics, which is why we know when recycling raw materials can and should be utilized in the manufacture of plastic parts. The manufacturing methods we use, injection molding and blow molding, are better suited to utilizing recycled materials than many other alternative methods. Recycled plastics are VMT Plastic’s most commonly used raw material – well over half of the plastic products we manufacture are made from recycled plastics.

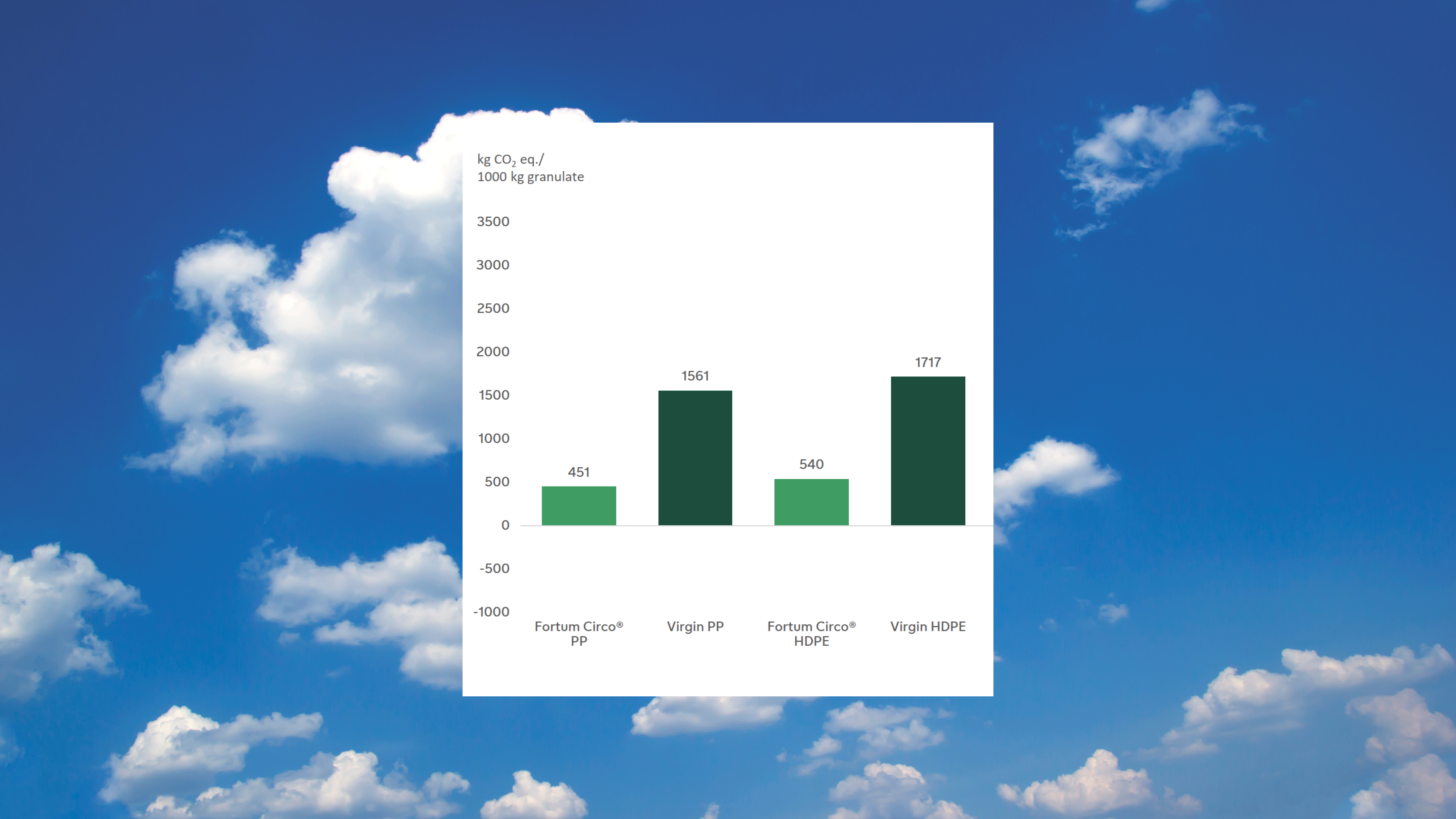

Choosing recycled material enables immediate emission reduction and helps in both calculating and lowering the company’s carbon footprint. Table: Fortum.

Choosing the raw material for a plastic product

When selecting the raw material for your plastic product, you can rely on VMT Plastic’s expertise. We always choose the raw material according to your product and its intended use. We use only responsible options, which is why we offer you truly sustainable solutions – our goal is to be a pioneer in our industry in utilizing recycled raw materials.

VMT Plastic closely follows the industry and is constantly searching for suitable raw materials that can be utilized in production. The benefit of our customers is always our priority, and that’s why we want to ensure that the raw material works as intended. We boldly and determinedly test various recycled materials to develop our operations and expertise – we have a vast database on how different recycled materials work and where they can be used. Therefore, we do not need to start searching separately for the recycled material suitable for your product.

We want to promote the use of recycled material and strive, whenever possible, to offer customers recycled material as the raw material for plastic products. We also utilize the waste material generated in our own production and refine it for reuse as raw material.

Keeping costs under control through product development

Through systematic development work, we are continuously increasing the use of recycled raw materials in our production. We have worked hard to acquire the necessary expertise to utilize recycled raw materials extensively in our production.

We always conduct our product development from the perspective of sustainable development. We also optimize the use of recycled plastic – we always use the right material suitable for the application. From the beginning of product design, we aim to make the products optimal and functional, ensuring that they achieve the required strength properties with minimal plastic usage.

We also ensure that the product lasts its intended lifespan, thus maximizing its lifecycle. We support you in product design and boldly suggest ways to reduce the amount of raw material needed, thereby also reducing costs. Using recycled material also provides an opportunity to reduce your carbon footprint.

Recycled plastic adapts to many uses

The most common recycled raw materials are mainstream plastics like polyolefins. For example, these materials are currently readily available from recycled sources:

- PP (polypropylene)

- PE (polyethylene)

- PA 6 (polyamide 6)

- PA 66 (polyamide 66).

High-quality recycled raw material requires a lot of work before it can be used to make new products. Recycled plastics are sorted, washed, regranulated, and transported to the right place. The cost difference between virgin and recycled raw material is not necessarily decisive, but when responsibility and environmental issues are considered, more and more people are turning to recycled raw materials.

Sustainability through cooperation

Fortum Circo, made by Finnish Fortum, is a versatile recycled plastic primarily made from household plastic packaging waste. Consumers can also influence the utilization of recycled plastics by recycling their plastic waste. We already widely use Fortum Circo in our production.

We utilize our extensive networks and eagerly seek new, high-quality recycled materials for which we try to find suitable applications. Finnish recycling raw material producers such as Suomen Rengaskierrätys are one source for which we are searching for suitable products.

We have already tested the latest cellulose and wood fiber options developed by Fortum and UPM, and we aim to find new applications for these materials through collaboration. Keskinen Recycling, specializing in plastic collection and processing, has been a key partner for us for a long time.

Don't hesitate to contact us.