Plastic Solutions

Key to your plastic solutions.

Partnership

We offer you solid plastic product and raw material expertise with over 50 years of experience.

Our goal is a cost-effective technical plastic solution for industrial needs. We recommend the manufacturing method, plastic raw material and additional services that best suit your project. It is important to us that your product is in the right place, at the right time and as it should be.

We are a reliable partner in the development of your product and service. Let’s raise your services and products to a new level together!

Solid plastics know-how

We use two plastic methods for manufacturing technical plastic parts

- Injection molding

- Blow molding

We help to choose raw materials for your product. We always recommend the raw material best suited to your project. We can also help with recycled plastic raw materials.

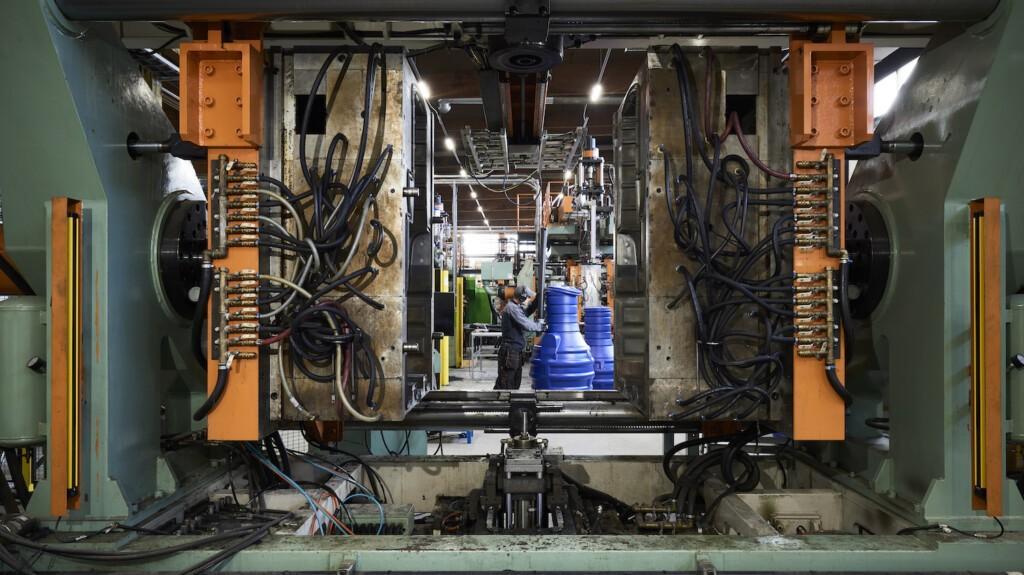

Blow moulding

VMT Plastic has solid know-how in technical blow molding. Cost-effective blow molding is suitable for serial production of hollow and thin-walled plastic products.

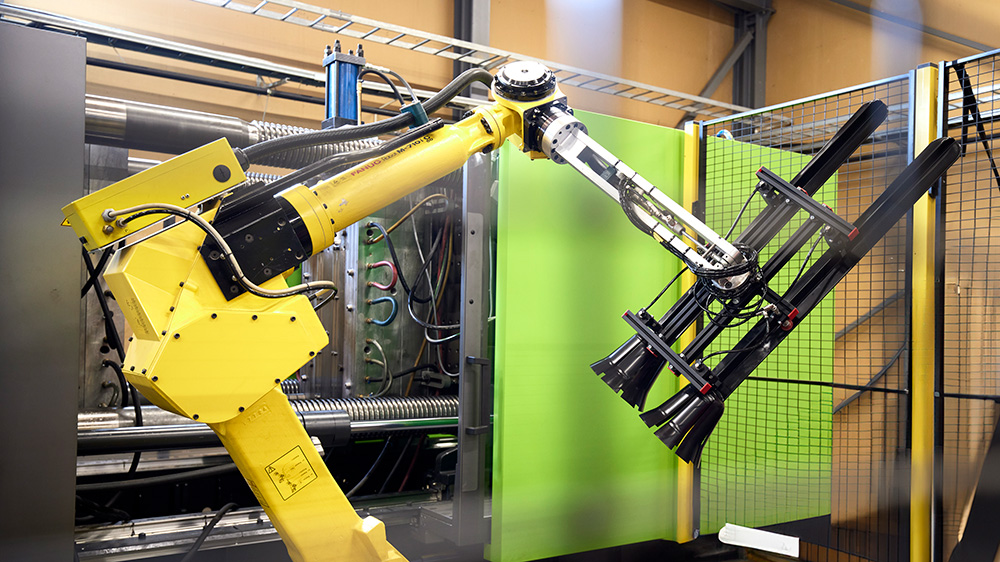

Injection molding

VMT Plastic offers versatile plastic solutions using the injection molding method.

Product development

We always tailor solutions according to the customer. Contact us as soon as the idea of a plastic solution comes to mind, this way we can maximize the potential of production methods and anticipate problems.

Assembly and sourcing

VMT Plastic offers comprehensive sourcing and subassembly services for plastic products.

Recycled plastic helps reduce the carbon footprint

Choosing recycled material enables immediate emission reduction and helps in both calculating and lowering the company’s carbon footprint.

Don't hesitate to contact us.